HORIZONTAL DIRECTIONAL DRILLING

ADC Drilling, LLC was established with a vision to offer an innovative alternative to traditional methods for installing product lines beneath various geographical and man-made features. These include streams, rivers, lakes, marshes, wetlands, beaches, estuaries, as well as artificial structures such as highways, railways, runways, sand dunes, and areas of ecological sensitivity or protected habitats.

Our team is deeply experienced in directional drilling, having successfully managed over 1000 Horizontal Directional Drilling (HDD) projects across both domestic and international terrains. Our expertise encompasses a wide range of challenging environments and soil types, including both rock and alluvial soils. We specialize in a diverse array of HDD projects, which involves drilling for the placement of power and communication conduits. This includes the installation of single ducts for fiber optics and multiple ducts for various types of cables, including copper and fiber. Additionally, our proficiency extends to the installation of product pipelines, demonstrating our comprehensive capabilities in the field of directional drilling. Our approach is designed to minimize environmental impact while ensuring the effective and safe installation of essential infrastructure.

Our expertise is rooted in the seamless integration and application of cutting-edge, high-quality drilling technology. This approach offers several key advantages:

- Minimized Community Disruption: Our techniques significantly reduce disturbances to local communities, maintaining the tranquility and routine of daily life.

- Lowered Liability Risks: By employing advanced methods, we decrease the likelihood of personal injury and property damage, ensuring a safer project environment.

- Enhanced Asset Longevity and Value: Our state-of-the-art technology contributes to extending the service life of utilities, thereby increasing their value for owners.

- Improved Worker Safety: We prioritize the safety of our workforce by utilizing technologies that reduce hazardous working conditions.

- Cost-Effective Restoration: Our approach minimizes the need for extensive restoration, leading to considerable cost savings in post-project cleanups.

- Precision in Installation: Our advanced drilling technology ensures accurate and precise installation, aligning with the highest standards of quality and efficiency.

As communities in the Kingdom of Saudi Arabia (KSA) continue to expand, there is a growing demand for enhanced infrastructure. ADC Drilling, a key player in this domain, offers Horizontal Directional Drilling (HDD) services catering to various sectors, notably oil and gas. Established in Saudi Arabia since 1997, ADC Drilling has gained a profound understanding of the region’s evolving landscape.

Their in-depth knowledge, coupled with a trustworthy and respected history, has enabled ADC Drilling to build long-standing relationships, working repeatedly with the same clients and prime contractors on numerous projects.

The ongoing construction boom in KSA has amplified the need for HDD services, particularly in the critical oil and gas infrastructure sectors. HDD is favored for its ability to efficiently install new or replacement lines with minimal disturbance across diverse environments, including both natural landscapes and urban areas. This method has emerged as the preferred solution for infrastructural development in the rapidly growing KSA.

What are the Benefits of Horizontal Directional Drilling in KSA?

ADC Drilling, LLC was established with a vision to offer an innovative alternative to traditional methods for installing product lines beneath various geographical and man-made features. These include streams, rivers, lakes, marshes, wetlands, beaches, estuaries, as well as artificial structures such as highways, railways, runways, sand dunes, and areas of ecological sensitivity or protected habitats.

Our team is deeply experienced in directional drilling, having successfully managed over 1000 Horizontal Directional Drilling (HDD) projects across both domestic and international terrains. Our expertise encompasses a wide range of challenging environments and soil types, including both rock and alluvial soils. We specialize in a diverse array of HDD projects, which involves drilling for the placement of power and communication conduits. This includes the installation of single ducts for fiber optics and multiple ducts for various types of cables, including copper and fiber. Additionally, our proficiency extends to the installation of product pipelines, demonstrating our comprehensive capabilities in the field of directional drilling. Our approach is designed to minimize environmental impact while ensuring the effective and safe installation of essential infrastructure.

What Type of Projects Are Ideal for Horizontal Directional Drilling in KSA?

In the Kingdom of Saudi Arabia, horizontal directional drilling (HDD) is highly suitable for a broad range of construction endeavors. Key applications of HDD in this region include:

- Installation of Utility Lines: Efficiently laying essential utility infrastructure with minimal surface disruption.

- Deployment of Communication and Fiber Optic Lines: Facilitating advanced telecommunications networks through underground installation.

- Waterline Construction: Ensuring reliable water supply systems are established with reduced environmental impact.

- Sewer Line Installation: Implementing underground sewage systems efficiently, avoiding major surface excavations.

- Gas Line Laying: Safe and unobtrusive installation of gas pipelines, crucial for energy distribution and consumption.

These applications highlight HDD’s versatility and effectiveness in meeting the infrastructural needs of the Kingdom of Saudi Arabia.

To evaluate whether Horizontal Directional Drilling (HDD) is the appropriate method for your project in KSA, consider the following professional criteria:

- Installation Length Requirements: Is the project extending beyond 180 feet?

- Urban Installation Context: Will the drilling occur within densely populated urban settings?

- Environmental Protection Considerations: Is the installation site located within environmentally sensitive or protected areas?

- Residential Area Installation: Are you planning to conduct drilling operations in residential neighborhoods?

- Subterranean Utility Density: Does the proposed drilling location have a high density of existing underground utilities?

- Water Table Concerns: Is the pipeline to be installed beneath the water table level?

- Soil Stability Analysis: What are the characteristics and stability of the soil in the proposed drilling area?

Assessing these factors will help in determining the suitability of HDD for your specific project needs in KSA.

As communities in the Kingdom of Saudi Arabia (KSA) continue to expand, there is a growing demand for enhanced infrastructure. ADC Drilling, a key player in this domain, offers Horizontal Directional Drilling (HDD) services catering to various sectors, notably oil and gas. Established in Saudi Arabia since 1997, ADC Drilling has gained a profound understanding of the region’s evolving landscape.

Their in-depth knowledge, coupled with a trustworthy and respected history, has enabled ADC Drilling to build long-standing relationships, working repeatedly with the same clients and prime contractors on numerous projects.

The ongoing construction boom in KSA has amplified the need for HDD services, particularly in the critical oil and gas infrastructure sectors. HDD is favored for its ability to efficiently install new or replacement lines with minimal disturbance across diverse environments, including both natural landscapes and urban areas. This method has emerged as the preferred solution for infrastructural development in the rapidly growing KSA.

What are the Benefits of Horizontal Directional Drilling in KSA?

ADC Drilling, LLC was established with a vision to offer an innovative alternative to traditional methods for installing product lines beneath various geographical and man-made features. These include streams, rivers, lakes, marshes, wetlands, beaches, estuaries, as well as artificial structures such as highways, railways, runways, sand dunes, and areas of ecological sensitivity or protected habitats.

Our team is deeply experienced in directional drilling, having successfully managed over 1000 Horizontal Directional Drilling (HDD) projects across both domestic and international terrains. Our expertise encompasses a wide range of challenging environments and soil types, including both rock and alluvial soils. We specialize in a diverse array of HDD projects, which involves drilling for the placement of power and communication conduits. This includes the installation of single ducts for fiber optics and multiple ducts for various types of cables, including copper and fiber. Additionally, our proficiency extends to the installation of product pipelines, demonstrating our comprehensive capabilities in the field of directional drilling. Our approach is designed to minimize environmental impact while ensuring the effective and safe installation of essential infrastructure.

What Type of Projects Are Ideal for Horizontal Directional Drilling in KSA?

In the Kingdom of Saudi Arabia, horizontal directional drilling (HDD) is highly suitable for a broad range of construction endeavors. Key applications of HDD in this region include:

- Installation of Utility Lines: Efficiently laying essential utility infrastructure with minimal surface disruption.

- Deployment of Communication and Fiber Optic Lines: Facilitating advanced telecommunications networks through underground installation.

- Waterline Construction: Ensuring reliable water supply systems are established with reduced environmental impact.

- Sewer Line Installation: Implementing underground sewage systems efficiently, avoiding major surface excavations.

- Gas Line Laying: Safe and unobtrusive installation of gas pipelines, crucial for energy distribution and consumption.

These applications highlight HDD’s versatility and effectiveness in meeting the infrastructural needs of the Kingdom of Saudi Arabia.

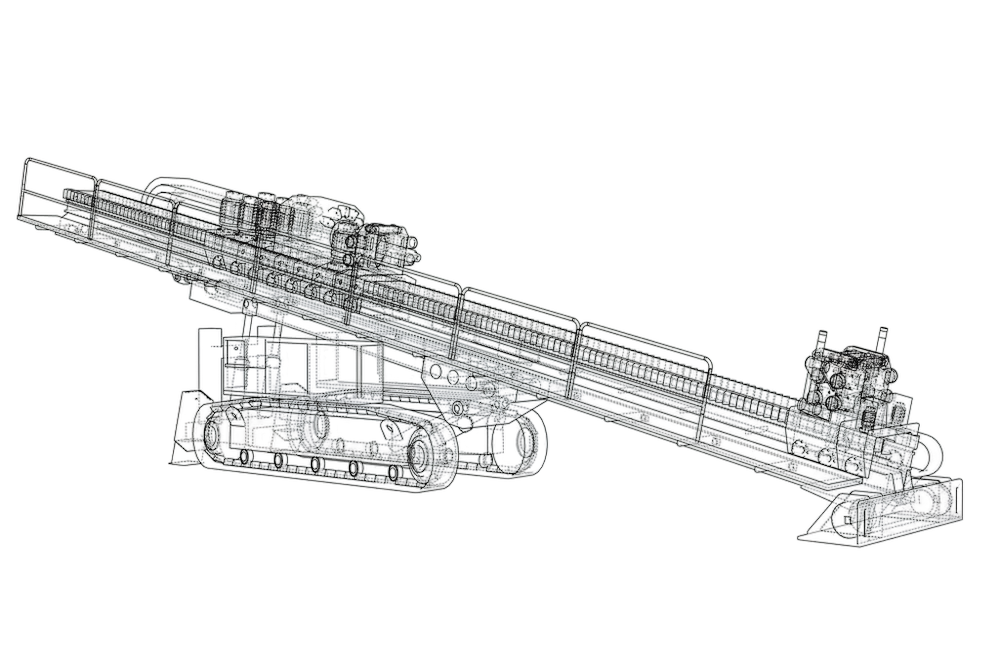

Horizontal Directional Drilling (HDD) is a pivotal technique in the construction of underground utilities, including natural gas and oil pipelines, particularly when it comes to new infrastructural developments. This method is highly effective for installing new or replacing existing lines beneath urban landscapes, roads, neighborhoods, and natural features like rivers and wetlands.

As a trenchless installation method, HDD stands out for its minimal environmental impact and reduced disturbance to surrounding areas. This technique is adept at installing pipelines over extensive distances, accommodating thousands of feet, and is versatile enough to handle a wide range of pipe diameters, from small to large. HDD’s cost-effective and environmentally sensitive approach makes it an increasingly preferred choice for oil and gas pipeline construction.

Several river crossings have been successfully completed, involving the installation of utilities beneath ecologically delicate waterways. This includes the placement of various utility pipelines, conduits for electric power & telecommunications, in a diverse range of underground soil conditions.

Our shore approach method involves drilling from the land towards the sea. This technique is increasingly being utilized for the installation of conduits that house ocean utility cables. ADC stands as a leading entity in this specialized area of underground construction.

In HDD, drilling through rock formations is challenging, but ADC has effectively tackled this by successfully drilling through extremely hard rocks. We use specialized mud motors and rock-specific tooling to efficiently install various utility pipelines and conduits in these tough conditions.

Using advanced horizontal directional drilling methods, we are able to execute lateral turns with tight radii. Our expertise allows us to design and drill using compound radius techniques for such complex scenarios.

We safeguard our delicate wetland regions through the use of Horizontal Directional Drilling (HDD). Our team has set a global record for the longest directional drill beneath wildlife preserves and wetland areas.

Description | Push/Pull Capacity | Practical Length Capacity |

|---|---|---|

| HRE 1100 | 1,100,000 lb. | Max Drill Lengths 8,000’ + Max OD 48” + Pipe |

| HRE 500 | 500,000 lb. of pullback | Max Drill Lengths 8,000’ + Max OD 48” + Pipe |

| American Augers DD-330 | 330,000 lb. | Max Drill Lengths 5,600’ Max OD 42” Pipe |

| American Augers DD-240T Rig | 240,000 lb. of pullback | Max Drill Lengths 4,400’ Max OD 36” Pipe |

| American Augers DD-210 | 210,000 lb. | Max Drill Lengths 4,400’ Max OD 36” Pipe |

| Vermeer 100×140 | 100,000 lb. | Max Drill Lengths 2,500’ Max OD 24” Pipe |

Our dedication is unwavering when it comes to ensuring a workplace devoid of accidents. We expect active participation, personal responsibility, accountability, and ongoing self-improvement from not only our employees but also our subcontractors, vendors, and clients. Safety is the cornerstone in the planning of all our directional drilling operations. Each member of our team is committed to playing a vital role in the effective execution of our Safety Program.